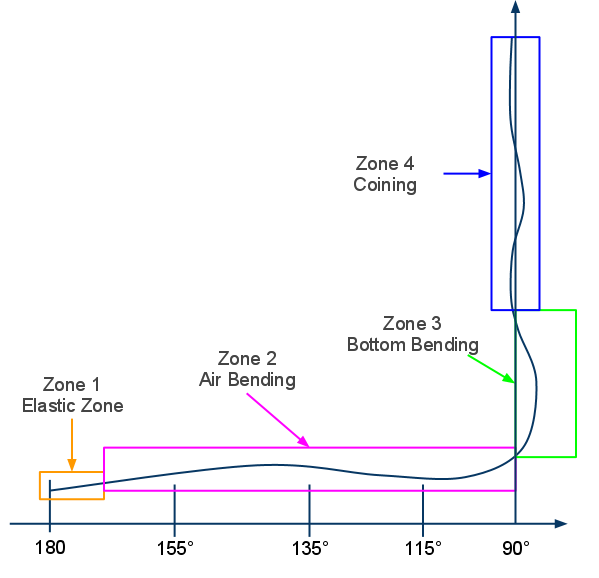

To achieve a 90 degree bend you must overbend the material past the desired bend angle and allow it to return to the desired shape with the springback.

Bend sheet metal more than 90 degrees.

As an example if you want to bend 24 gauge sheet metal at a 90 angle the calculation would be.

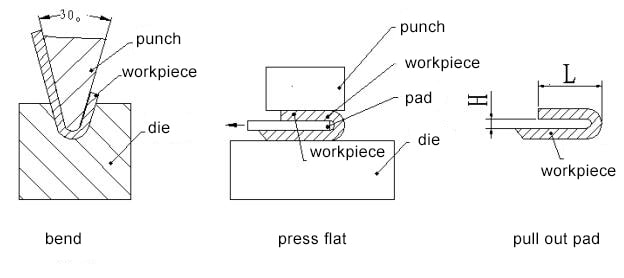

Often the offset will be one workpiece thickness in order.

After bending the sheet we need to do some measurements as shown in figure 2.

Actually there are special polymer tools available to avoid any kind of tool marking let alone scratches.

Geometry of tooling imposes a minimum bend dimension.

Edge bending is another very common sheet metal process and is performed with a wiping die.

However if folder radii do not work for you we can manufacture parts using our press brakes.

It has a big advantage over wipe bending or v bending it does not scratch the material s surface.

90 degrees bend angle.

Bending a brittle metal beyond its limits could cause the metal to snap and break.

Another way to bend edges is through rotary bending.

Also wiping die employed in edge bending must have a pressure pad.

The bend attains 90 degrees at a point in the die space that s about 20 percent the material thickness as measured from the bottom of the v die.

From there we can calculate the k factor and the bend deduction.

From the bottom of the v die see figure 5.

Joggling also known as joggle bending is an offset bending process in which the two opposite bends are each less than 90 see following section for how bend angle is measured and are separated by a neutral web so that the offset in the usual case where the opposite bends are equal in angle is less than 5 workpiece thicknesses.

The diagram shows one such mechanism.

We will start by calculating the bend allowance.

For bend angles smaller than 90 they are usually defined as the length from the apex to the edge for bend angles larger than 90 they are usually measured from the tangent of the bend to the.

In fact press brakes are more flexible and can bend certain parts that the folder just cannot do.

Figure 2 illustrates the sheet that is bent with the bend angle of 90 degrees.

For instance 0 062 in thick cold rolled steel will bottom once the punch nose is 0 074 to 0 078 in.

Rotary benders can also bend sharper corners than 90 degrees.

Edge bending gives a good mechanical advantage when forming a bend.